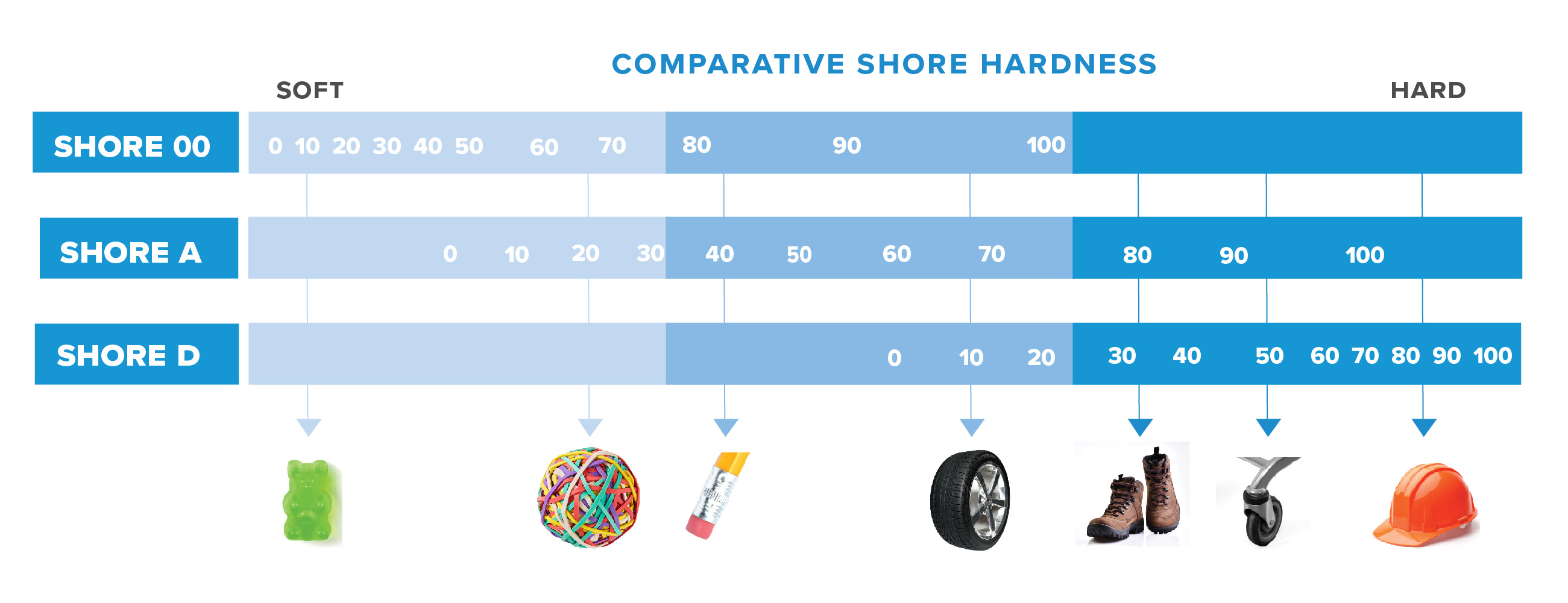

Hardness refers to a material’s resistance to indentation and can be measured on a multitude of different scales based on the type of indenter and force used. For elastomers, the Shore OO, Shore A, and Shore D scales are most commonly used with a ~1N, ~8N, and ~44N force applied respectively. For each scale, a material that indents 2.54mm at the applied load is given a ‘0’ hardness value and a material with no indentation is given a ‘100’ hardness value. Typical hardness values for different materials are shown in the table above.

The primary challenge with hardness is that it only measures indentation in a thick material (greater than 3mm thickness), and many elastomeric parts are thinner than 3mm. Additionally, hardness, as measured by the Shore measurement, does not describe the most important material behavior. Haptics is another characteristic of a “soft” material that refers to its tactile sensation. In many cases, hardness is confused with the haptics of a material, however, these two features are independent of one another. A Shore OO gel material can have a very dry touch sensation while a Shore D elastomer can be very grippy. In general, we refer to haptics on a continuum of tactile sensation.

Sticky - Tacky - Grippy - Neutral - Dry - Soft - Silky - Greasy

While the descriptors at the extremes may be considered unpleasant, the application dictates where the material should fall along the spectrum.

- A sticky material feels like glue and leaves a residue on the skin when touched.

- A tacky material feels like tape; it will resist release when touched but not leave any residue.

- Grippy materials resist touch but easily release from the hand.

- Neutral refers to a material with no noticeable tactile sensation.

- Dry, soft, and silky all refer to degrees of generally pleasant tactile sensation with a silky feel having the easiest sliding feel when touched without any residue.

- A greasy material goes beyond silky into the potentially unpleasant realm where a material is slippery and leaves a residue when touched.

Generally speaking, these tactile sensations are independent of hardness, though material texture will significantly impact how the finished product feels. Lack of texture will make a material feel grippy, whereas a slight texture makes it feel soft or even silky. Finally, a more aggressive texture moves a material back towards the grippy end of the spectrum. The hardness of the material and its ability to deform due to the pressure of the touch can impact the contact surface area and thus the perception of grip.

Beyond hardness and haptics, the last sensory attribute of a material to consider is hand. Hand is a textile industry term referring to how a material drapes when held horizontally with no load. A supple material will easily drape when held horizontally while a rigid material will not. The hand of a material is more of an attribute of its modulus.

Focusing on just one of these three sensory attributes can result in a final material that is not optimal for an application. The best way to identify the ideal material solution is to understand the differences and define material requirements early in the design process. A thorough review with a team of material experts is recommended. Our dedicated team is ready to help you grasp what’s possible.